In general places, ventilation plates may be used less. Generally, ventilation floors and all-steel antistatic floors are used together, and the perforations on the ventilation plates are of different shapes. There are round and square holes and large holes. In fact, these big holes all have a big effect. The size and shape of the hole directly affect the ventilation rate, therefore, today xiaobian will give you a brief introduction to what is the ventilation rate of the ventilated floor!

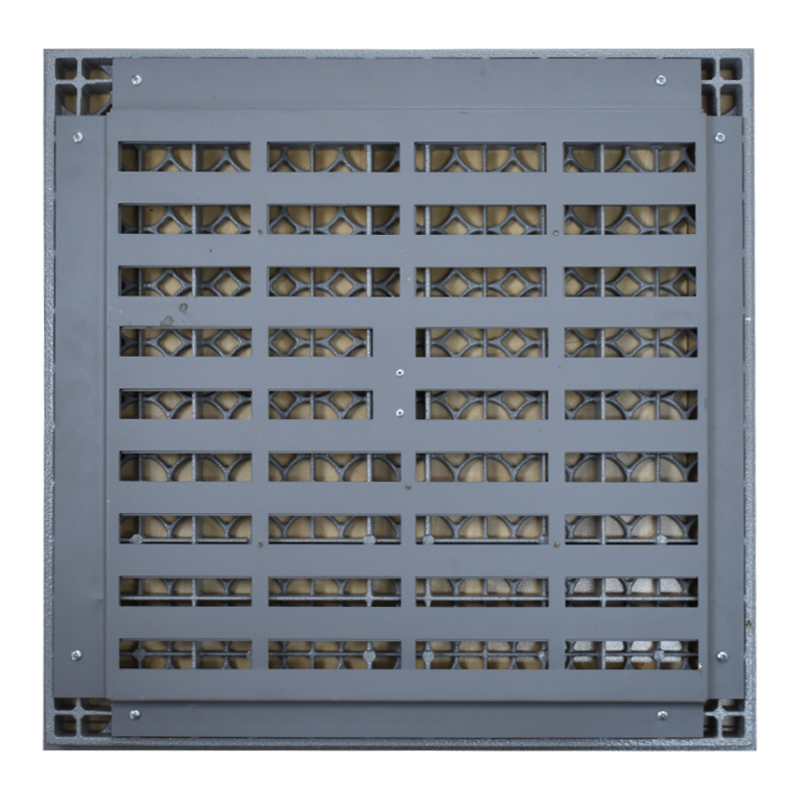

First of all, let's learn about the products. The ventilation plate is made of all steel, and the surface is punched with HPL or PVC veneer. The panel adopts high pressure punching, the bottom is square tube, manual welding. Imported electrostatic spray, around conductive strip edge, bracket and beam are made of steel molding, screw can be adjusted at any height.

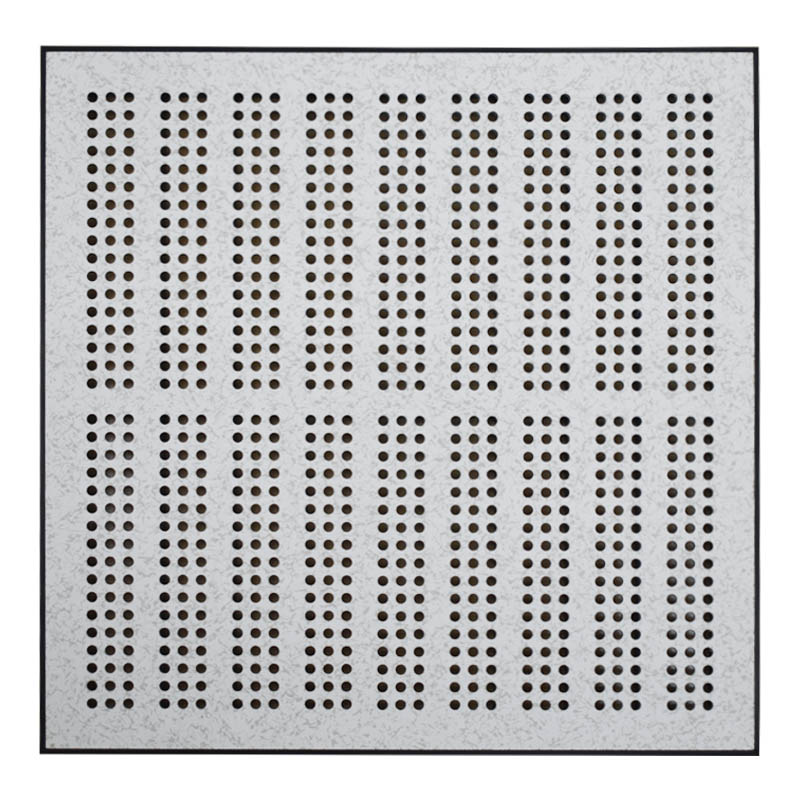

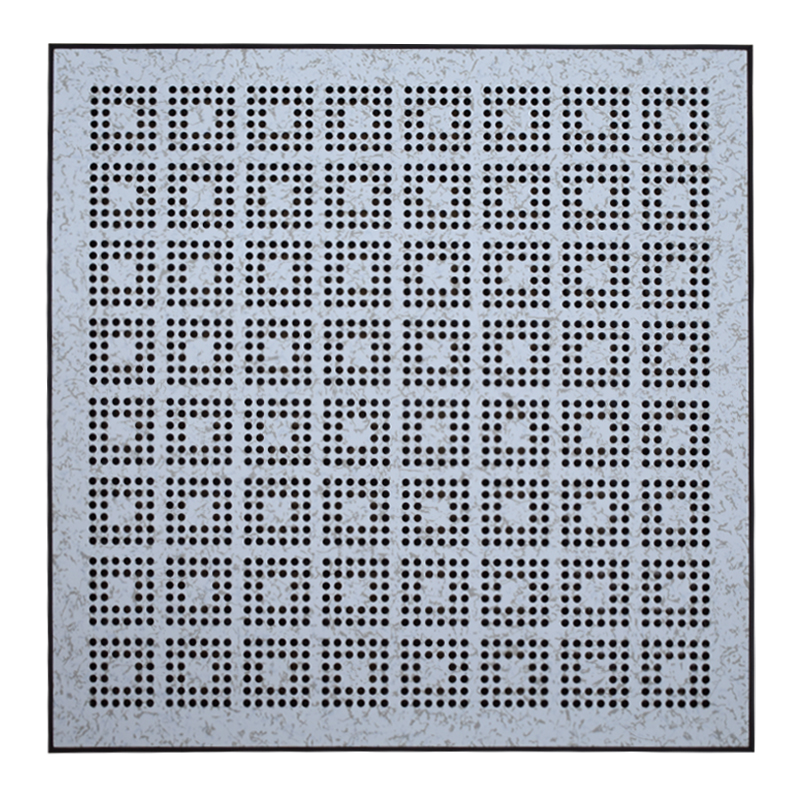

After understanding the structure of the ventilation board, let's take a look at what is going on with those large and small holes? In fact, those holes are used for ventilation at the bottom, the ventilation rate of holes of different sizes is not the same, the conventional ventilation rate is 17%-50%, when the ventilation rate is 20.8%, a total of 918 holes; When the ventilation rate is 41.2%, there are 576 holes in total. When the ventilation rate is 43.8%, there are 324 holes in total. When the ventilation rate is 39.5%, a total of 128 holes, these knowledge of some commonly used data, and some more special can also be customized.

What are the selection conditions of the ventilation plate? What kind of ventilation plate is good? This is actually need to choose according to their own site equipment, the greater the ventilation rate, the better the ventilation effect, the greater the carrying capacity, the anti-static index must reach the NATIONAL standard, the index between 10^6~10^9 ohm.

Post time: Mar-08-2022