There are a lot of anti-static floor on the market now, style type is also a variety of, dazzling, so specific what kind of anti-static floor? How should we choose? The types of ESD floors are as follows:

1, all steel anti-static floor

Is the selection of high wear-resistant melamine HPL fire-proof board or PVC as the surface layer (the northern area due to the dry climate, it is not easy to use HPL fire-proof board veneer) steel shell layout base material, other based on whether there is black tape and endless and edge of the points. Usually the project business choose non-standard type (electrostatic conductivity and load bearing and other aspects are difficult to reach the demand), because of the low price, the high demand of the gb type

2, aluminum alloy anti-static floor

Products are made of high quality cast aluminum profiles, which are formed by stretching. The surface layer is high wear-resisting PVC or HPL stick, conductive glue is posted and become, have the result that base material does not rust for a long time to use, useful processed the commodity shortcoming of compound floor and whole steel floor next, and the advanced anti-static floor that tailor-made, but its cost is too high.

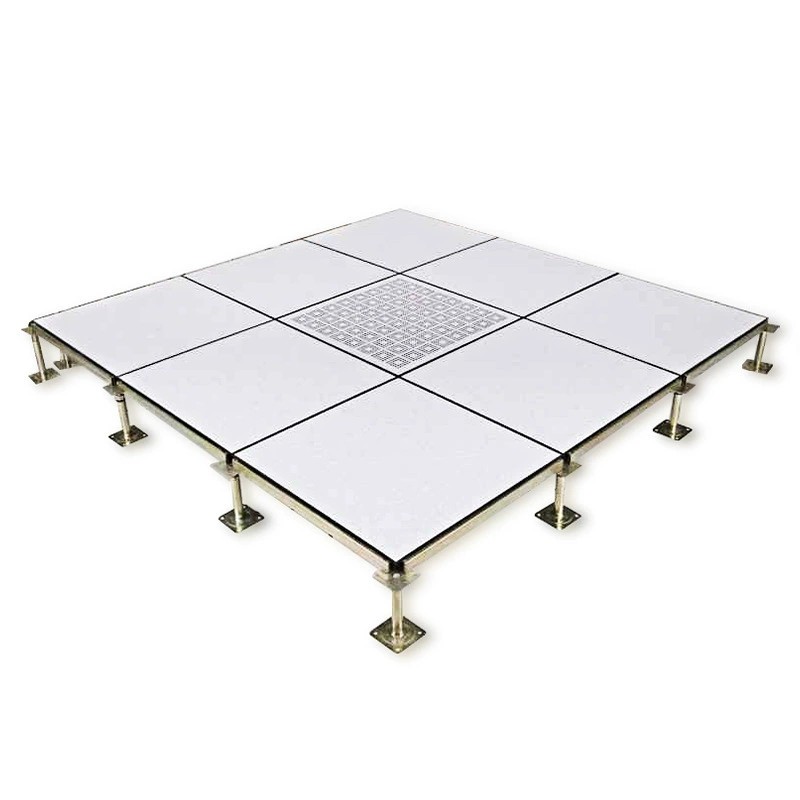

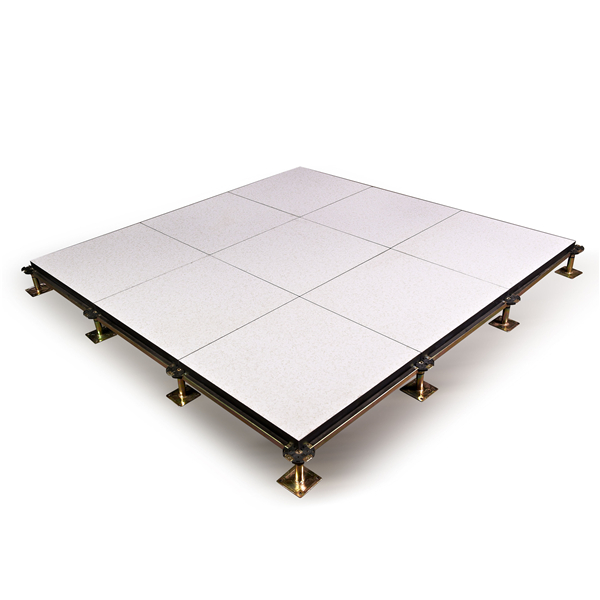

3, ceramic anti-static floor

Choose antistatic ceramic tile as surface layer, composite steel floor or cement particleboard, near conductive adhesive tape edge processing (no adhesive tape in the ceramic floor

Knock against simple drop porcelain). With anti-static function stability, environmental protection, fire prevention, high wear resistance, high life (use life of more than 30 years), high bearing capacity

(average load 1200kg/ square meter), waterproof, moisture-proof, good decoration and other advantages, suitable for all kinds of computer room. The disadvantage is that the floor itself is heavy (more than 15Kq for a floor), which has certain influence on the bearing capacity of the floor; Other also need professional installation workers can be installed, otherwise the device will not be flat.

Methods for selecting an ESD floor:

1, the first need to accurately build the computer room required antistatic floor area (or blocks) and the number of various accessories, and leave a margin to avoid shape

To spoil or lack.

2, fully know the types and quality of antistatic flooring produced by manufacturers, as well as various skills and functional indicators. The skill function of antistatic floor mainly points to its mechanical function and electric function.

3. The load of the antistatic floor should be determined based on the weight of the heaviest equipment in all the equipment in the machine room, so as to avoid the lasting deformation or damage of the floor caused by the excessive weight of some equipment.

4, antistatic floor by the influence of external environmental conditions change little, that is, not because of the external environment temperature is too high, too low have significant elasticity, that is, in the machine

When the room temperature is slightly higher, the antistatic floor expands and expands, which cannot be removed and replaced; When the temperature is low, the antistatic floor shortens and becomes loose. Antistatic floor

The amount of shortening affected by the environment should be less than 0.5mm, and the deflection of the board surface should be less than 0.25mm.

Mechanical function first consider its bearing capacity, wear resistance. The whole antistatic floor device in the lap of the truss beam, after leveling the anti-electric floor, its bearing capacity should reach the uniform load is greater than 1000kg/m2, the anti-static floor on any part of the assembly load should be greater than 300kg, in diameter

When the loading point of 6cm bears 300kg load, the deflection should be less than 2mm and there is no persistent deformation. Adjustable support should be able to accept more than 1000kg of straight load, and the board should have certain friction resistance.

The electric function is mainly the system electric Yang, electrostatic voltage, the appearance of shen Yang, the system electric Yang should be 1050-1080, at the temperature of 21+1.5℃, relative temperature

When the degree is 30%, the electrostatic voltage of the antistatic floor should be lower than 2500V, and the external resistance value should be 1052-1082

Post time: Mar-01-2022